Northwest Industries Big Sky Business Journal

June 13, 2018

Skills Gap

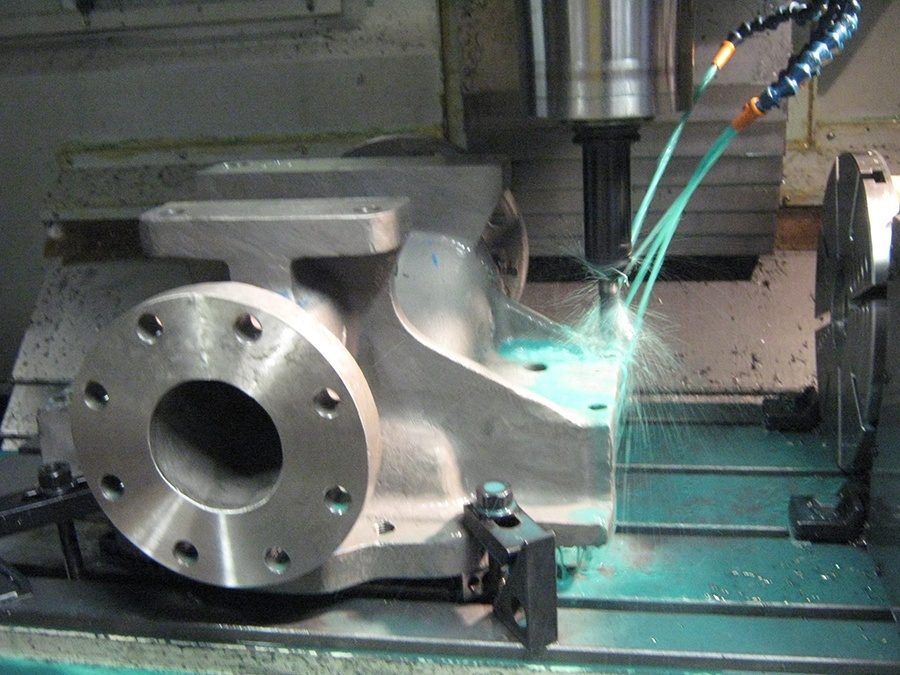

April 11, 2020There are some things in this world that benefit from a hands-on, hand-made approach. And there is a recent movement towards the creation of furniture, clothing, leatherwork, etc. But there is also a place for precision craftsmanship, and the sureness of absolute accuracy. If you don’t know how CNC machining works, it’s a somewhat straight-forward process: computer software is programmed with a plan that it will use to control machine tools and recreate the plan precisely. Also, the machine itself can use plasma cutters and water-cooling jets that help the machine to create precisely and quickly. The advantages in precision over a manually-operated machine are numerous.

The results produced from a CNC machine are also repeatable, and with that repeatability in production also comes a repeatability in accuracy. A manually-powered machine could not make the same claim.

There are numerous uses for the accuracy and precision of a CNC machine. For starters, the CNC machine can produce high volume parts and at a quick rate. The efficiency with which a CNC machine operates can save you both time and money. And because the CNC machine is programmable, it can be used for a variety of tasks. That means that if you have an idea, then the CNC’s technology could help bring that idea into reality. Northwest Industries could help you both design and produce a prototype.

If you have any questions about how CNC technology could help you, either to begin a run—both short runs and long runs on parts are encouraged—on a part or create something new, beginning with a prototype, then remember to call the CNC experts at Northwest Industries today.