Pumps

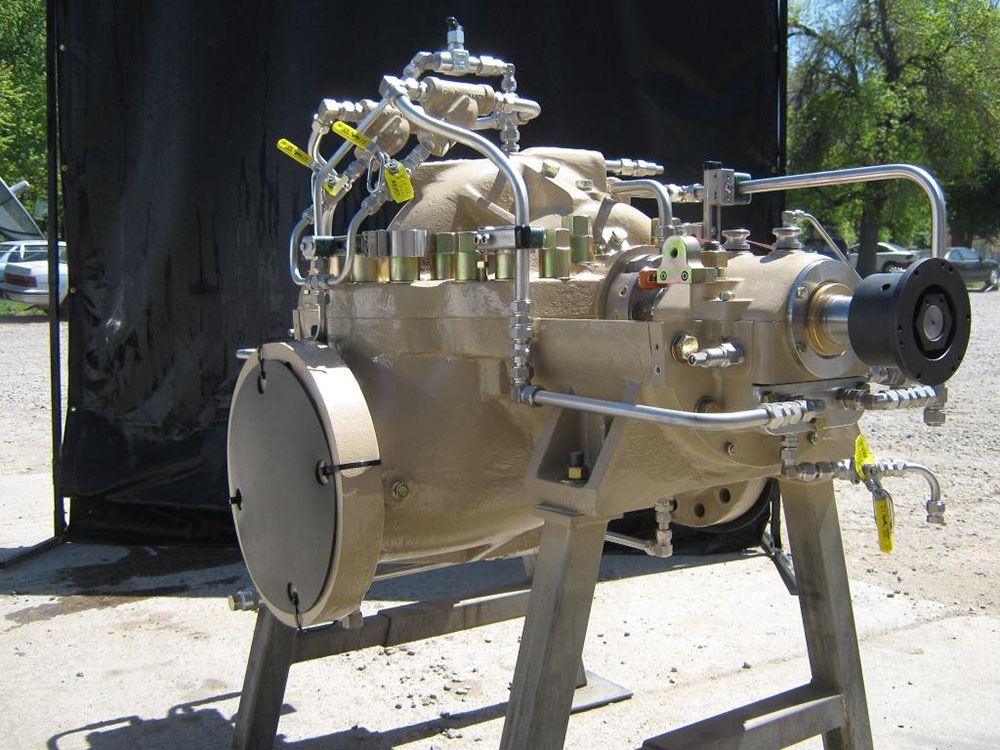

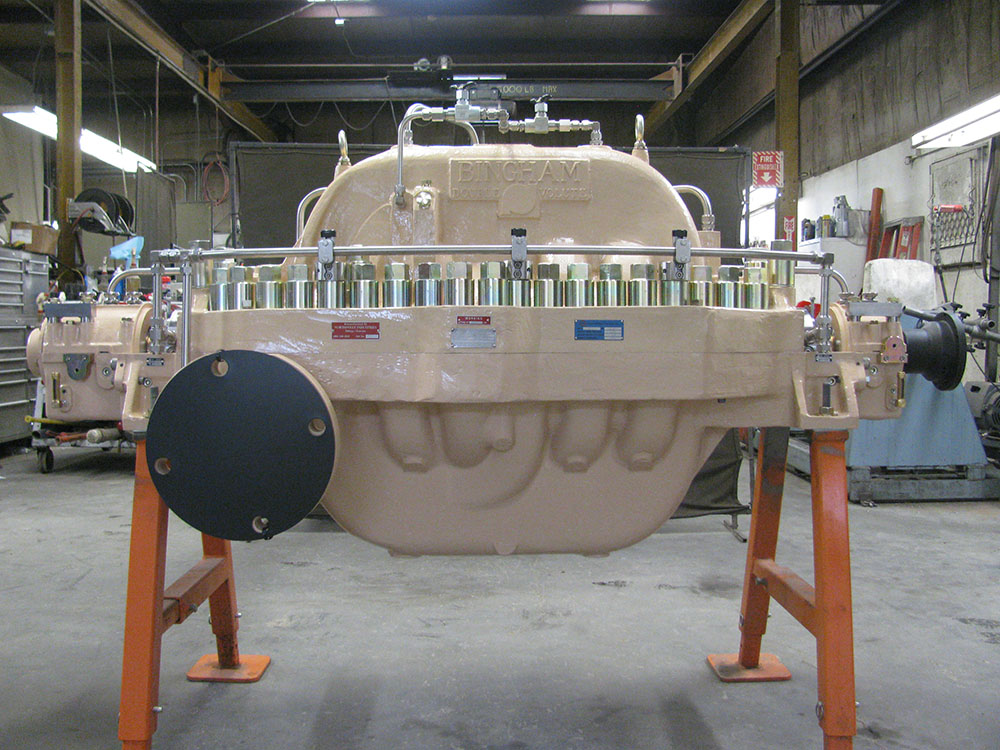

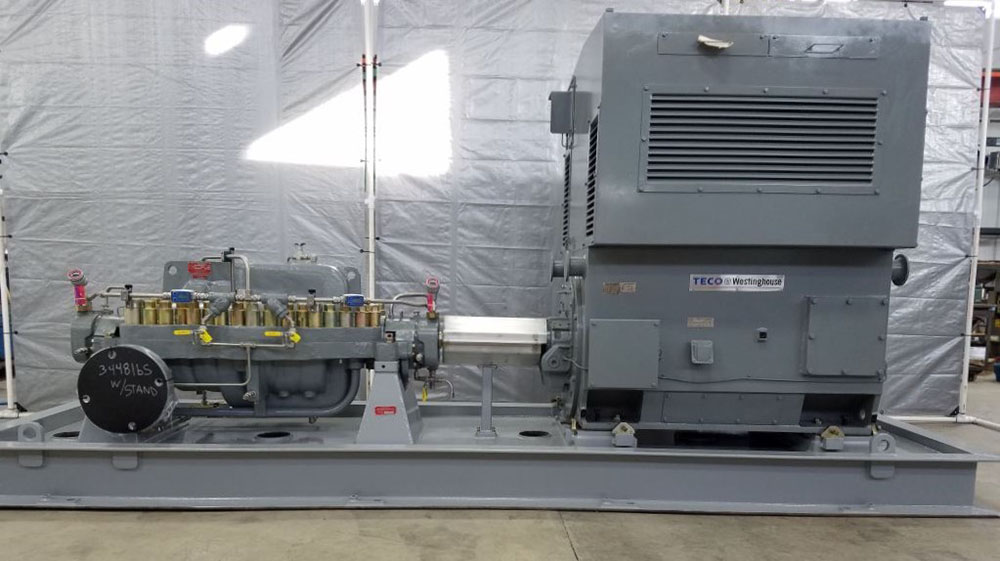

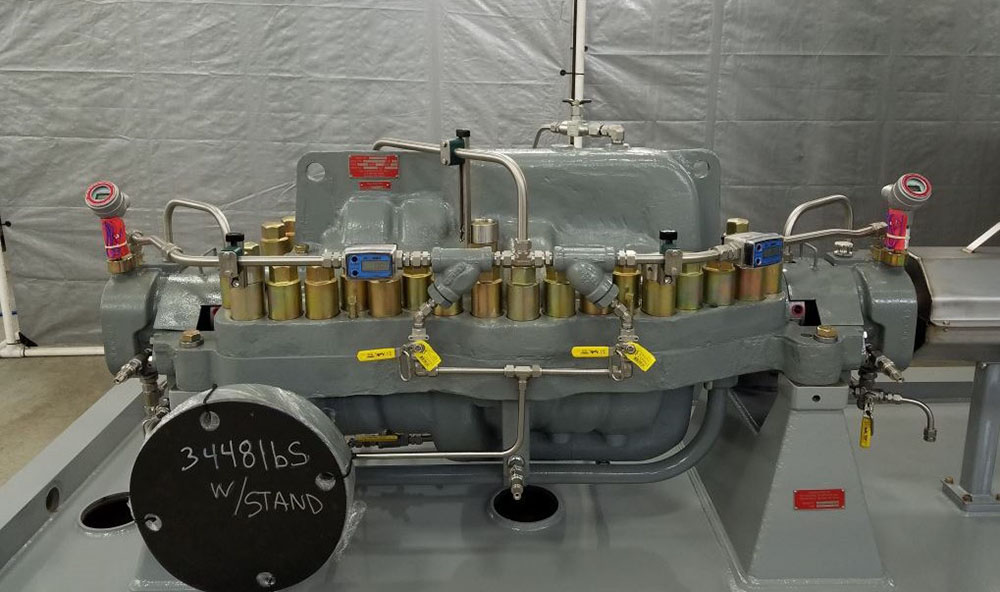

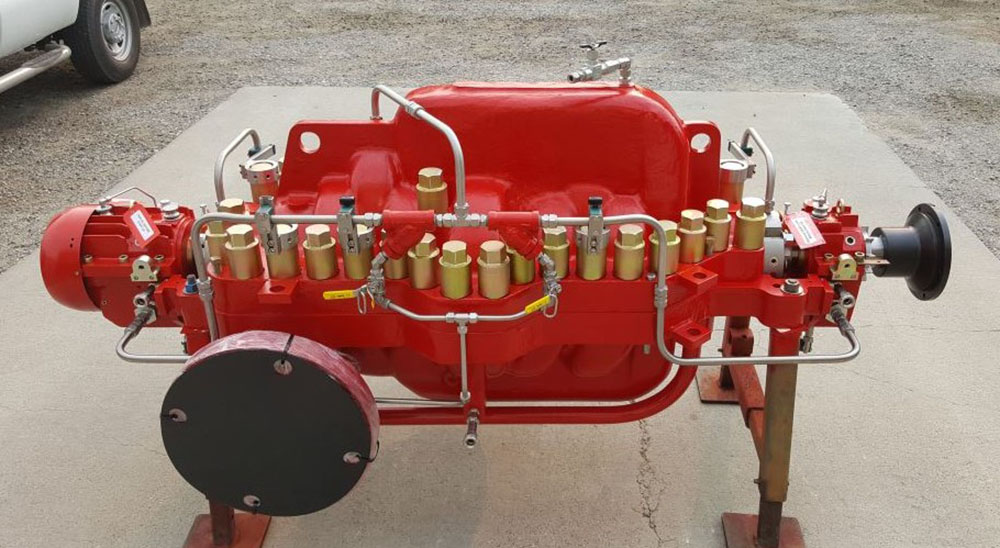

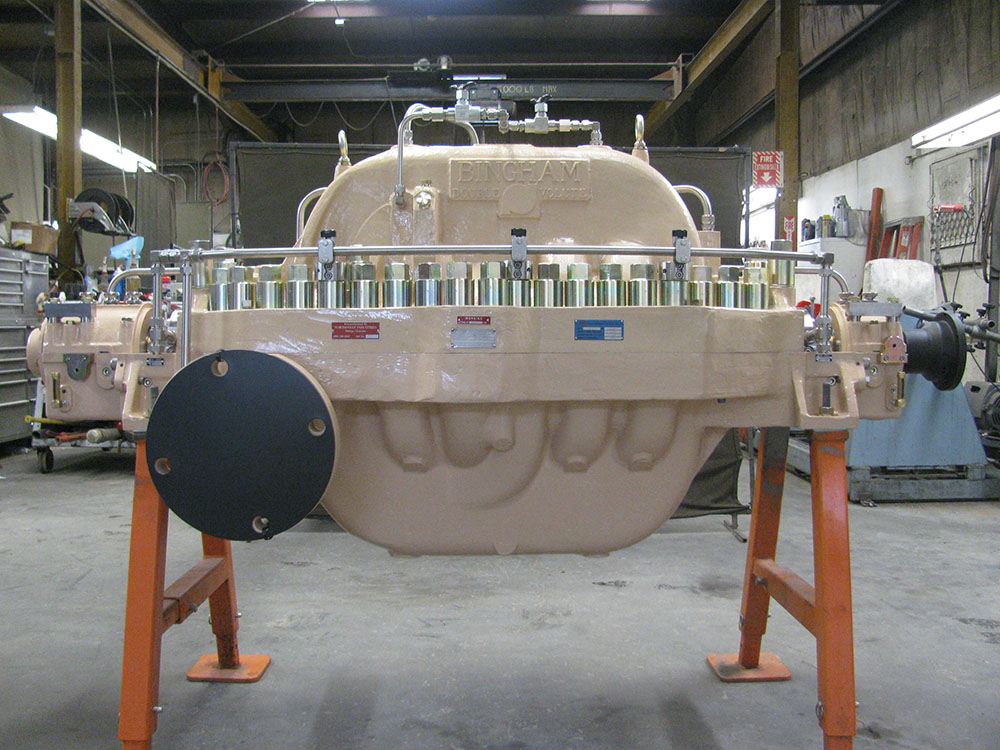

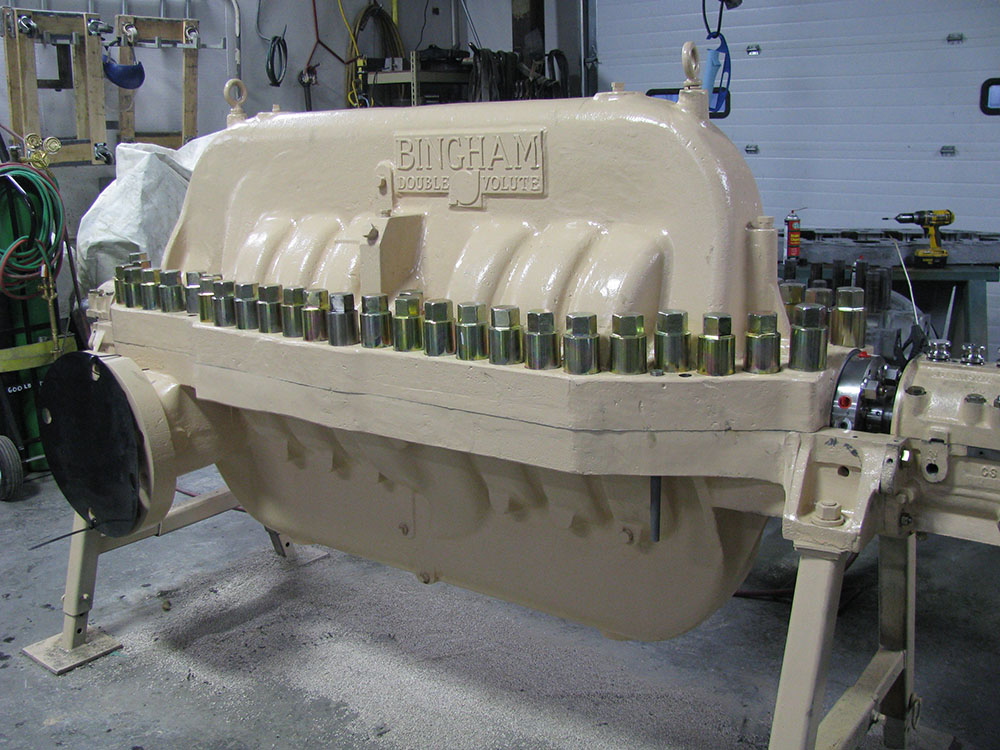

INDUSTRIAL SERVICE CENTER for reconditioning and servicing of all types of pumps and components. Serving the petroleum, refinery, pipeline, municipal water plants, commercial and agricultural industries. Pump and Motor Skid design and manufacturing for complete “turnkey” systems. We collaborate directly with your engineers and designers to put together a system that fits your needs.

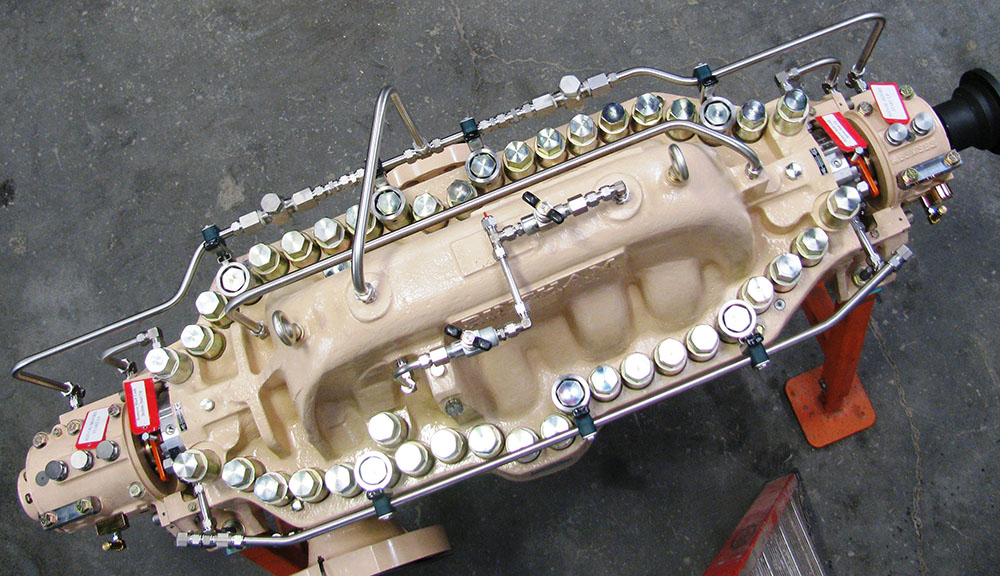

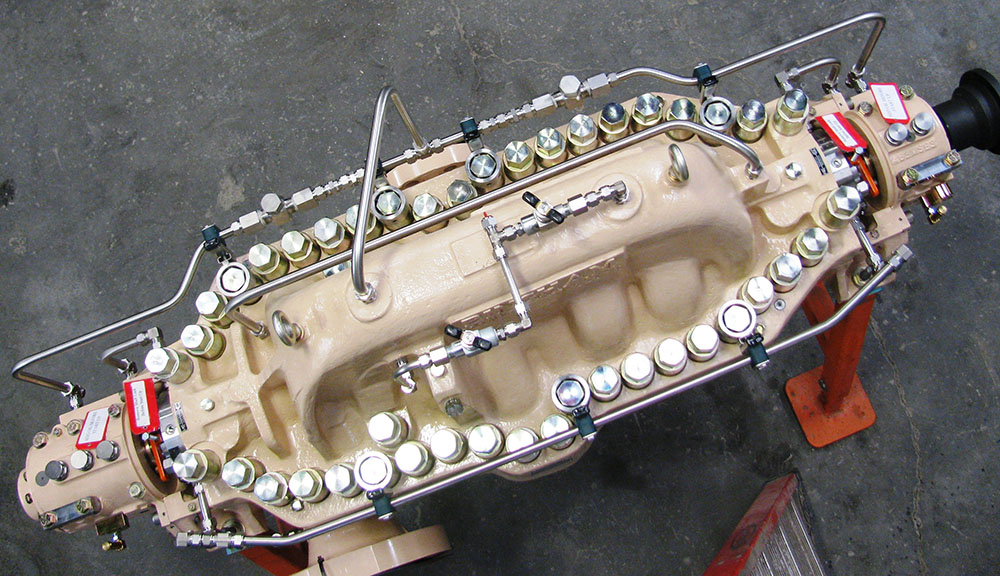

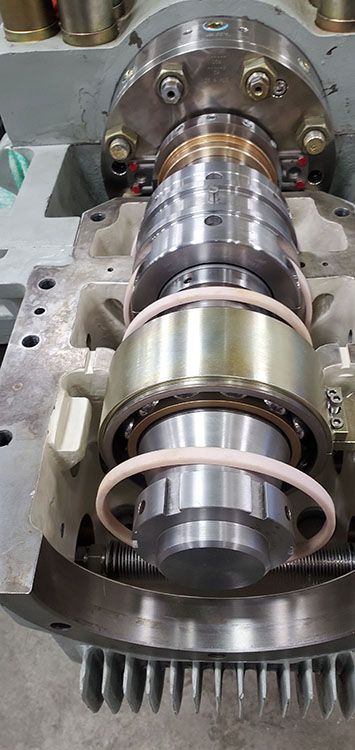

EFFICIENCY UPGRADES to get the most out of mainline pumps with high-tech materials such as non-metallic composite Vespel®CR-6100, Boulden PERF-Seal® design, HVOF Tungsten Carbide coatings (Jet Kote or Tafa), PEEK and other carbon fibers of your choosing. Let us help you extend service life through increased pump efficiency and less maintenance with these products … even with bearing housing upgrades that will help manage MTBF (Mean Time Between Failure). Efficiency improvements help recuperate upgrade costs with better performance and less maintenance. Give us the opportunity to work with your team.

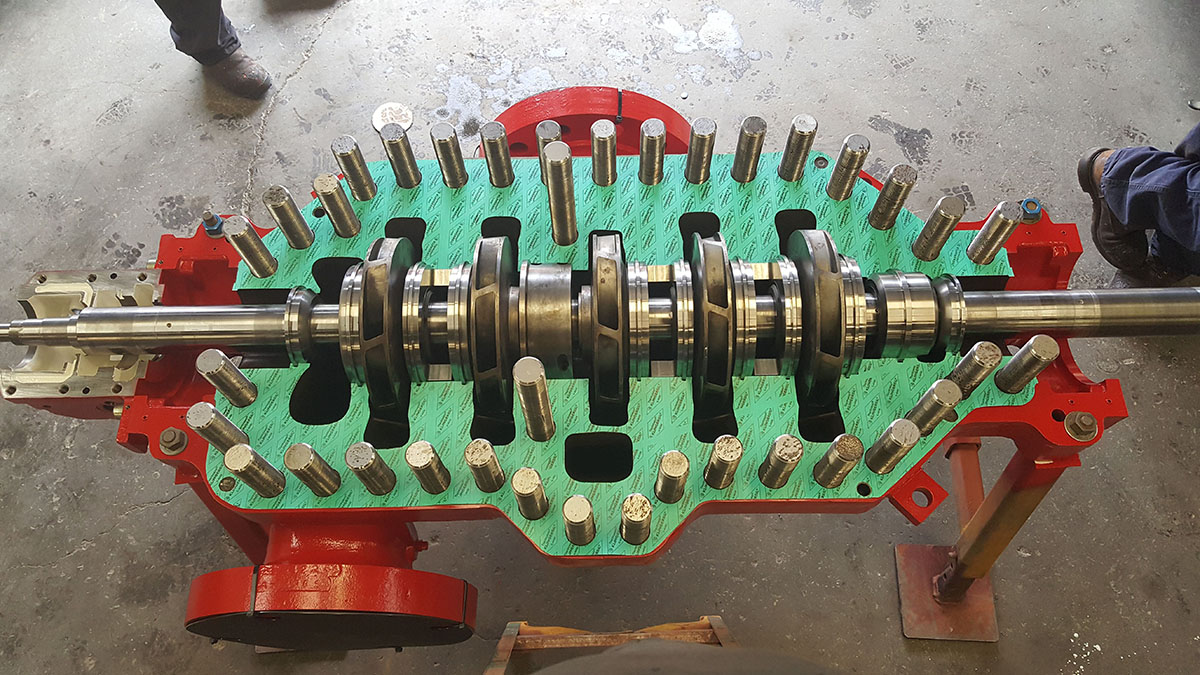

PERFORMANCE BENEFITS of asset improvement using non-metallic materials. There are additional benefits and savings from running closer tolerances and clearances: they reduce interstage recirculation, dampen vibration, and non-galling tendencies with smoother performance with less power consumption. These benefits include extended service life of Mechanical Seals and bearings—less maintenance (MTBF). These tighter tolerances, reduced clearances of 50% less than API-610, require professional rebuild standards (trueness of faces and registers to achieve perpendicularity, concentricity, straightness to a common centerline) for extended service life. So, whether you are rebuilding a pump fitted with OEM materials or improved high-efficiency materials, knowing how to achieve these tolerances is critical. This is where it is important to use a rebuild center that understands and knows how to achieve this alignment. As the end user you can reap the benefits of your asset improvement. This is the reputation our company has built over many years.

SPECIALTY TOOLS AND UPGRADE PARTS to make your operations Technician Safe and Dependable. We warehouse a variety of stock items for alignment accessories; a complete Flush Tubing mounting system to streamline your seal flush system and add professional appearance to you pump station; a seal gland Facing Tool system to extend Mechanical Seal life with zero face runout; a Safety Hoist that mounts easily and offers on the job Technician Safety; 24/7 warehousing service ( Call 406-248-2813 or e-mail office@nwimt.com for details).

COMPLIANCES: API-610, SAE and ANSI Standards, and whatever written standards your company requires we are ready to comply in every way possible. We have an open-door policy to examine our company operations and Quality System.

COMPLIANCE MANAGEMENT: We are DOT Title 49 CRF compliant and member of pipeline compliance organizations such as: OSHA, NCMS, ISNETWORLD, VISA, DISA, EQUILON, NIPSCO, etc. (e-mail office@nwimt.com for details).

DOCUMENTATION: We keep controlled records of disassembly and assembly findings and submit a complete Rebuild Package Report at the end of a project. Engineered drawings for manufactured or repaired product as-built inspection record. All critical drawing dimensions by two inspectors’ initials (QC & QA) becomes the permanent archived record. We are a full disclosure operation, and drawings are a part of the Rebuild Package.

Our company builds on a great principle of serving others so that they can be successful. We look forward to helping your Team in 2023, which may be more challenging than at any other time in our nation’s history … but there is one thing that the Team at NWI has learned and is committed to that COOPERATION will win over competition EVERY time. We understand budget constraints that plant and maintenance managers adhere to because we are a business as well. Our Team Leaders will communicate pump internal and external issues with you throughout the project and explain the pros and cons of repair or not to repair so that your team has the information necessary to get the best rebuild possible. Service life and performance is of foremost importance to get the most out of an asset. We are here to SERVE, and you are in the driver’s seat for success.

Check our Catalog for Flush Tubing hardware! Call 406-248-2813 or Toll Free 888-817-2511 for more details.