Automation vs Human Labor

July 2, 2020

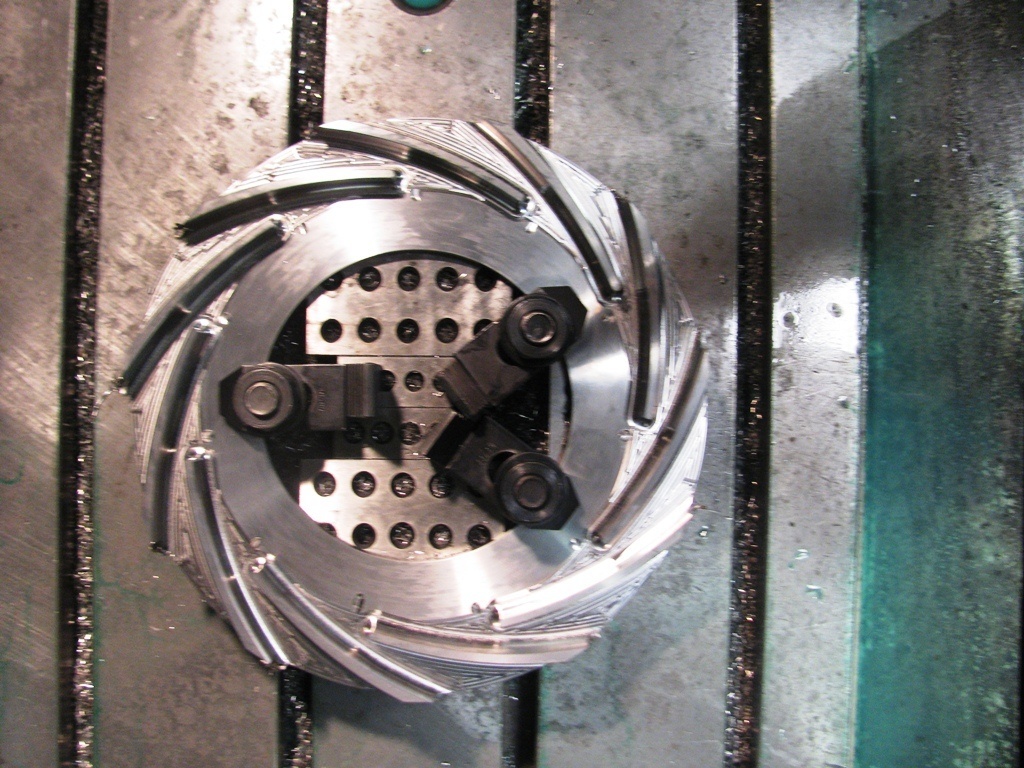

Precision with CNC Machining

August 20, 2020CNC manufacturing has fairly recently become indispensable to manufacturers. As modern manufacturing adopts a more automated approach, CNC manufacturing and the computer code that drives the process, industrial machinery such as lathes, routers, drills, and millers are operated by computers, and the results are precise and repeatable. Here are a few of the practically limitless benefits to this type of modern manufacturing…

CNC machining is accurate. It’s an efficient way to produce something precisely, and with predictably repeatable results. The things being built are built with speed and efficiency. And all the major operations required to produce something are automated, increasing the speed and quality of thing being manufactured. And efficiency gains are also apparent when you consider the amount of time production can continue without a break. It may sound silly, but a machine doesn’t require a break due to fatigue.

And the applications for reproducible accuracy is unparalleled in manufacturing processes. And the reduction of errors in the manufacturing process saves on the amount of waste. And the high level of accuracy also makes the parts completed to be unique and original; other manufacturers won’t be able to simply steal or precisely duplicate the designs. And it’s also possible that because things are built by machines, with software to deliver precise results, things that weren’t previously possible to be built by hand are suddenly possible.

CNC Machining is the future of many manufacturing processes, and Northwest Industries is committed to the technology. It’s a technology that’s precise but also one that can help reproduce parts in high volume, and save customers both time and money. If you have any questions about CNC machining, or would like to discuss with the professionals an upcoming project, then call Northwest Industries today.